Many question whether rubber is recyclable, and the answer is a resounding yes. Recycling rubber not only conserves resources but also presents an opportunity to reduce the environmental impact of waste rubber. With an array of techniques at our disposal, transforming rubber into new products holds ecological and economic promise. However, it’s crucial to consider the recycling sites and the quality of recycled rubber products, as some practices may inadvertently cause environmental harm.

The industry dedicated to recycling rubber is evolving, working towards improving the efficiency and quality of recycled products. Is rubber recyclable? As consumers, it’s important to stay informed and participate in responsible recycling to ensure that the benefits of this practice are fully realized, minimizing the potential for negative environmental effects.

Understanding Rubber Recycling – Is Rubber Recyclable

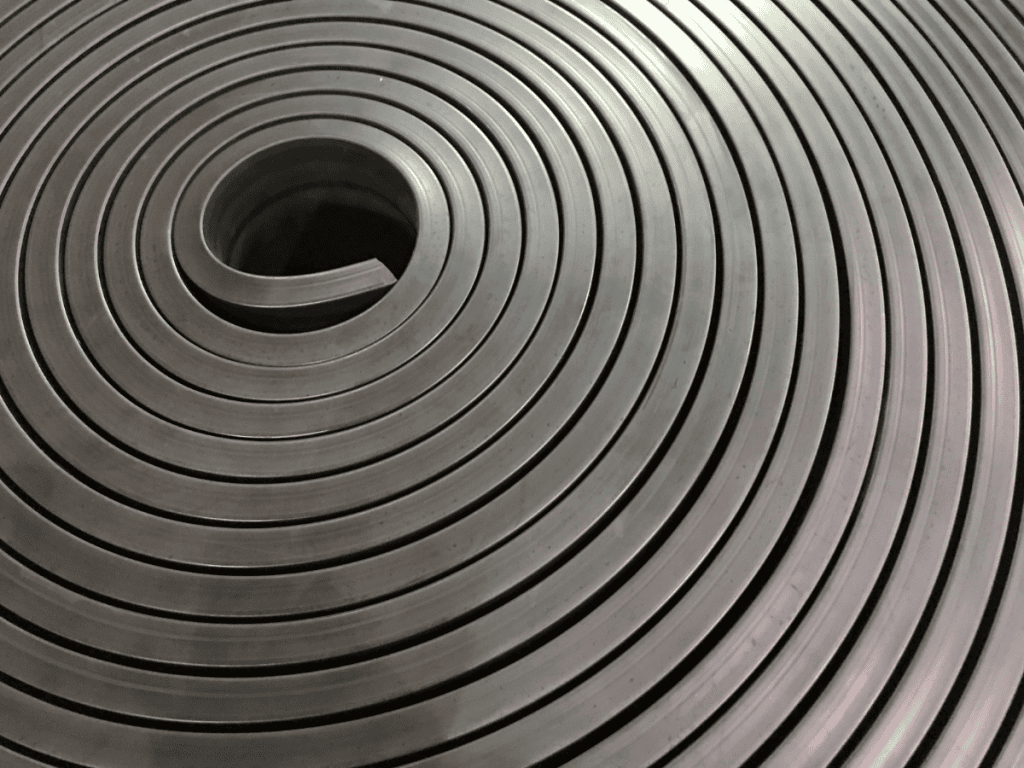

Rubber recycling is a complex procedure that breathes new life into waste rubber. It’s a process supported by an industry dedicated to transforming discarded rubber materials into valuable raw materials. The journey of waste rubber from mere trash to a resourceful commodity is fascinating and speaks volumes about our capabilities to innovate for sustainability.

The typical rubber recycling process involves several stages, from the initial collection to the final transformation. These include shredding rubber, sorting to remove contaminants, and a crucial step known as devulcanization. This intricate process ensures that waste rubber is not left to languish in landfills but reenters the market as a useful product.

The Importance of Recycling Rubber

Recycling rubber is of paramount importance. It benefits the environment by reducing the amount of waste rubber in landfills, which can take centuries to decompose. By recycling, we also reduce the need to produce new rubber, lowering the demand for natural resources and energy, thereby curbing pollution and conserving the ecosystem.

Furthermore, there’s an entire industry dedicated to recycling rubber, which signifies its economic significance. This industry helps manage waste rubber, creates jobs, and drives innovation in developing new methods and products from recycled materials. The importance of recycling rubber cannot be overstated—it’s a key component in our quest for sustainability.

Categories of Rubber: Natural vs Synthetic

Rubber comes in two primary categories: natural and synthetic. Natural rubber is derived from the sap of the Hevea brasiliensis tree and boasts superior elasticity and resilience. Its ability to stretch extensively is remarkable. On the other hand, synthetic rubbers are man-made materials designed to mimic or enhance certain properties of natural rubber. Both types have distinct characteristics that affect their recycling processes and the quality of the end products.

The Role of Rubber Composition in Recycling

The composition of waste rubber plays a critical role in recycling. The variations in properties between natural and synthetic rubbers dictate the methods required to break them down and repurpose them. For instance, devulcanization, essential for recycling, must be tailored to address the chemical structure of the waste rubber in question. Therefore, understanding the composition is key to efficient and effective rubber recycling.

From Waste to Wealth: The Journey of Recycled Rubber Products

I’ve seen firsthand how discarded rubber can be transformed into valuable products. The process begins with the collection of waste rubber, much of which comes from old tires. These tires are then put through a series of processes to create new materials and products. For instance, crumb rubber, derived from waste tires, is used in various applications, from sports fields with rubber infill to playground surfaces.

The journey of recycled rubber doesn’t stop there. This versatile material is also used to manufacture various goods, such as mats for automobiles and homes. The transformation from waste to wealth provides economic benefits and contributes to a more sustainable environment by giving new life to what was once considered trash.

The Rubber Recycling Process Detailed

Recycling rubber involves several key steps to convert waste rubber into reusable raw materials. Initially, rubber items, particularly tires, are gathered and subjected to powerful shredding machines. The shredded pieces are then sorted to remove any non-rubber components. It’s quite an intricate system, ensuring only rubber progresses to the next recycling stage.

Once the waste rubber is purified, it undergoes devulcanization. This process reverses the vulcanization of rubber, restoring its plasticity and allowing it to be reformed into new products. From there, the recycled rubber can be molded into useful items such as mats, proving that the lifecycle of rubber extends far beyond its initial use.

Initial Collection: The First Step to Recycling

At the recycling center where I volunteer, the initial collection of rubber products is a crucial first step. Here, we focus on gathering as many rubber items as possible, emphasizing tires. This is because rubber can be recycled multiple times, making it a valuable resource. Community members bring their used tires to our facility, or we collect them from local businesses eager to dispose of them responsibly.

These tires are the primary contributors to the recycling stream. Our job at the recycling center is to ensure they are prepped for the next stages. It’s a rewarding process, knowing that we’re diverting these materials from landfills and reducing the need for new rubber production, which, in turn, conserves natural resources.

Breaking Down: Shredding and Crushing Rubber Materials

The breaking down of rubber into smaller pieces is a task that our heavy-duty machines easily handle. The rotary shear shredder is particularly effective, with its counter-rotating barbs tearing through rubber and reducing it to manageable sizes. This step is crucial as it prepares the rubber for further processing, making it easier to handle and sort.

The Creation of Crumb Rubber

Crumb rubber is a fine material created from grinding waste tires. This material is in high demand in our facility due to its versatility. Whether for athletic fields, playgrounds, or even as an additive in asphalt, crumb rubber provides a sustainable solution for various industries looking to incorporate recycled materials into their products.

Advanced Sorting: Separating Rubber from Contaminants

Following the shredding process, we use advanced sorting to separate rubber from contaminants. We meticulously extract steel fibers and other impurities from the rubber waste stream using shaking screens, wind sifters, and vacuum suction systems. It’s a detailed process that ensures the highest quality of rubber is available for recycling.

The purity of the rubber is crucial for the quality of the final recycled product. As such, our sorting protocols are rigorous and designed to ensure that only clean rubber progresses to the devulcanization stage. This attention to detail is what allows us to recycle rubber with confidence, knowing that the end product will meet high standards.

Reversing Vulcanization: The Devulcanization Process

One of the most fascinating aspects of rubber recycling is the devulcanization process. It involves the selective breakup of chemical bonds within waste rubber, specifically targeting sulfur links without degrading the rubber’s physical properties. This process effectively returns the rubber to a state where it can be reshaped and reused.

Once devulcanized, the rubber can be mixed with virgin rubber to create new compounds. This mixture retains the strong physical properties necessary for high-quality rubber products. It’s a sophisticated process that respects the intricate chemistry of rubber, ensuring that recycled materials are just as robust as their newly manufactured counterparts.

Innovations in Rubber Devulcanization Techniques

Recent breakthroughs in devulcanization techniques have been remarkable. By refining the process that breaks the chemical bonds in waste rubber without damaging the material’s physical properties, we can now produce higher-quality devulcanized rubber. This rubber can be mixed with virgin materials to create compounds that maintain strong performance and durability.

Additional Rubber Recycling Methods

Beyond devulcanization, other methods of recycling rubber are employed to handle the wide variety of waste rubber we encounter. These techniques are adapted to suit the specific types of rubber we process, ensuring that we can recycle as much material as possible. This dedication to innovation keeps our recycling practices flexible and efficient.

Whether molding rubber into new products or finding alternative uses for recycled rubber, the industry continually evolves. This adaptability is key to maximizing the potential of waste rubber, turning what could be discarded into valuable, sustainable resources.

The Freezing and Pyrolysis Approaches

Freezing rubber with liquid nitrogen is another method we use when rubber gets frozen, it can be processed in mills and ground to create granules. This approach is effective as devulcanization for certain types of waste rubber. Pyrolysis, on the other hand, involves heating rubber to process its recycling, converting it into liquid oil through a condensing system, which can then be used in a combustion system to generate electrical energy.

The Environmental and Economic Benefits of Rubber Recycling

The benefits of recycling rubber are numerous and far beyond the obvious environmental impacts. By diverting rubber from being dumped in landfills, we reduce pollution, conserve natural resources, and mitigate the harmful effects of rubber production. Economically, it creates an industry that provides jobs and generates cost-effective and sustainable products.

Conserving Energy and Natural Resources

I’ve always been passionate about how recycling rubber can help conserve energy and natural resources. Natural rubber, derived from Hevea brasiliensis, is an unsaturated rubber with highly resilient characteristics. Recycling reduces the need to tap into these natural sources, preserving them for future generations.

Furthermore, the energy required to produce new rubber from scratch is significantly higher than what’s needed to recycle it. In my experience, utilizing recycled rubber conserves resources and reduces our overall energy consumption, contributing to a more sustainable industry and planet.

Mitigating Landfill Overcrowding with Rubber Recycling

One of the most pressing issues we face is waste rubber disposal, which contributes to landfill overcrowding. Recycling can alleviate this burden on our landfills, allowing them to serve their purpose without becoming overwhelmed. The process of turning waste rubber into useful materials means less rubber ends up taking up valuable space in our landfills.

By focusing on recycling, we’re managing waste effectively and promoting a circular economy where materials are reused rather than discarded. This approach has significant implications for our environment and the sustainability of our resource management practices.

Reducing Environmental Pollution Through Rubber Reuse

Rubber materials have the potential to cause significant environmental pollution if not managed properly. When left in landfills, they can release toxins or catch fire, leading to air pollution. Additionally, stagnant water in discarded tires can breed diseases or contaminate water bodies, harming aquatic life.

Through the reuse of rubber materials, we can dramatically reduce these pollution risks. My commitment to rubber recycling is driven by the desire to protect our environment from these hazards and to promote a healthier, cleaner world for all.

Renewed Rubber: Creating Eco-friendly Products

Rubber tire recycling has grown tremendously, with millions of tires repurposed annually. This keeps rubber tires out of landfills and contributes to reducing CO2 emissions. As someone engaged in rubber tire recycling, I take pride in knowing that over two hundred million tires are kept from being dumped in landfills each year, making a substantial impact on the environment.

Tire-Derived Products and Their Market Impact

Crumb rubber and rubberized asphalt are prime tire-derived products that have significantly influenced the market. Crumb rubber is utilized in various applications, including sports fields and playgrounds, and as an additive in molded products. Meanwhile, rubberized asphalt, a blend of traditional asphalt with crumb rubber, is gaining traction for its superior durability and noise reduction properties on roadways. These innovations extend the life of recycled rubber and contribute to a more sustainable environment by reducing reliance on virgin materials.

Spotlight on Innovation and Industry Insights

Innovations in the rubber recycling industry are transforming how we manage natural rubber and synthetic materials. Companies like Genan exemplify the advanced production process necessary for efficient rubber production. Their state-of-the-art facilities take in various types of tires and meticulously separate them into rubber powder, steel, and textile fibers. This meticulous separation is crucial as it ensures the purity of raw materials for further use, setting a high standard in recycling and disposal.

Another key player in the sector is Green Distillation Technologies (GDT), which, in collaboration with CarbonScape, has pioneered converting carbon from rubber recycling into high-value graphite. This partnership underscores the potential for rubber waste to be upcycled into valuable commodities, thereby revolutionizing the disposal of used tires and pushing the boundaries of what can be achieved with rubber and plastic remnants.

Trailblazers in the Rubber Recycling Industry

Trailblazers in rubber recycling are making substantial strides in converting waste rubber into reusable raw material. Through meticulous sorting and devulcanization, these innovators maximize the potential of what was once considered waste. This demonstrates the rubber recycling industry’s viability and underscores the commitment to environmental stewardship.

By transforming waste rubber into a valuable commodity, these trailblazers reinforce the importance of sustainable practices. Their efforts help reduce the environmental impact of rubber waste and pave the way for future advancements in the field.

New Horizons in Rubber Waste Management

With the continuous evolution of recycling technologies, new horizons in rubber waste management are emerging. Innovators are exploring more efficient ways to repurpose waste rubber, minimizing environmental impact and maximizing resource recovery. The industry is on the cusp of breakthroughs that could redefine the lifecycle of rubber products.

The Evolution of Thermoplastic Elastomers from Recycled Rubber

The development of thermoplastic elastomers (TPE) from recycled rubber marks a significant milestone in the industry. These versatile materials combine the flexible properties of elastomers with the recyclability of plastics, offering a wide range of applications while also contributing to sustainability efforts. The evolution of TPEs illustrates the potential to create high-quality materials without relying solely on virgin resources.

Examining the Properties and Applications of TPE

Thermoplastic elastomers (TPE) created from recycled rubber exhibit remarkable properties such as elasticity, durability, and recyclability. These materials are increasingly used in automotive, consumer goods, and medical industries, offering an eco-friendly alternative without compromising performance or quality. The diverse applications of TPEs are a testament to their significance in the sustainable materials market.

Breakthroughs in Rubber Recycling Technology

Recent breakthroughs in rubber recycling technology are revolutionizing how we handle waste rubber. Innovations in devulcanization and material processing make it possible to recover and reuse rubber more efficiently. These advancements are beneficial for the environment and economically advantageous, as they create new opportunities for industries to utilize recycled rubber in high-value applications.

Recent Advancements and Their Implications

The rubber recycling industry is witnessing exciting advancements, particularly in production. Technological developments enable the creation of high-quality rubber powder from natural rubber, which can be used as a raw material in various industries. These innovations are crucial in enhancing the efficiency of recycling and disposal, potentially reshaping the future landscape of rubber production.

Engaging with Experts and Community Involvement

Engaging with experts is critical to advancing rubber recycling practices. By tapping into the knowledge of industry leaders, communities can benefit from insights into more effective methods of managing waste rubber. Collaboration between experts and local initiatives can drive innovation and inspire collective action towards more sustainable recycling and disposal solutions.

Community involvement plays a pivotal role in the success of rubber recycling programs. Through educational events and campaigns, individuals can learn about the importance of recycling and how to dispose of used tires properly. This collective effort contributes to environmental conservation and fosters a sense of responsibility and stewardship among community members.

Rubber Recycling Experts and Their Contributions

Experts in rubber recycling are instrumental in transforming waste rubber into a valuable resource. Their contributions range from developing advanced recycling technologies to advocating for responsible disposal practices. By sharing their knowledge and expertise, these professionals help shape a more sustainable future for the rubber industry.

How Consumers Can Participate in Rubber Recycling

I can contribute to rubber recycling by properly disposing of used tires and supporting products made from recycled materials. By being mindful of my consumption and disposal habits, I play a part in reducing the environmental impact of waste rubber. I can make a difference by participating in recycling programs and purchasing decisions.

Community Engagement: Events and Education for Better Recycling Practices

Community engagement is essential for promoting better recycling practices. By participating in events and educational programs, I can learn about the benefits of rubber recycling and how to contribute effectively. Such initiatives are crucial for raising awareness and encouraging responsible behavior towards waste rubber.

The Future of Rubber Recycling

The future of rubber recycling is bright, with ongoing innovations and a growing awareness of sustainability. As new technologies emerge, the potential for recycled rubber to replace virgin materials in a wider array of products grows. This shift promises environmental benefits and economic opportunities for industries and communities alike.

Anticipated trends in rubber recycling technologies point towards more efficient and cost-effective methods of transforming waste rubber into high-quality raw materials. With the continuous evolution of these processes, the rubber recycling industry is poised for significant growth and impact in the years to come.

Projected Trends in Rubber Recycling Technologies

The rubber recycling industry is expected to see significant technological advancements, further enhancing recycling processes’ efficiency and effectiveness. Innovative methods like improved devulcanization techniques are projected to transform waste rubber into usable materials that are more streamlined and economically viable.

Anticipated Challenges and Opportunities Ahead

While the rubber recycling industry faces challenges such as fluctuating market demands and the complexity of recycling processes, there are also substantial opportunities for growth. By overcoming these obstacles and harnessing emerging technologies, the industry can expand its reach and continue to make a positive environmental impact.

The Impact of Rubber Recycling on Society and Environment

Recycling rubber materials significantly reduces our carbon footprint by mitigating the amount of natural rubber and other raw materials needed for production. When rubber tires are repurposed into recycled materials, they help reduce solid waste and the energy-intensive processes of manufacturing new products. Recycled rubber offers a sustainable alternative to disposing of shredded tires in landfills, thus crucial in preserving environmental health.

Furthermore, using recycled rubber in creating new products fosters a circular economy that benefits society by providing eco-friendly options. It prevents the accumulation of rubber waste, threatening land and aquatic ecosystems. By recycling rubber, we are conserving resources and paving the way for innovation, leading to greener living and improved well-being for communities worldwide.

The Continuous Effort to Recycle Rubber Efficiently

Efforts to recycle rubber efficiently are ongoing, focusing on processing mechanical items like surgical gloves and transforming tire rubber into valuable commodities. By recycling four tires, for instance, we can create longer railroad ties that are more resilient than traditional materials. Furthermore, when tire rubber is cleaned and processed, it contributes to the production of rubber that prevents waste while solving important challenges, such as reducing injuries for athletes and creating lower-impact hospital floors for nurses.

Recycled rubber is produced from worn tires through a straightforward process, leading to innovations like rubberized asphalt and energy-absorbing playground surfaces. These efforts are essential for environmental sustainability, as they reduce greenhouse gas emissions that would otherwise result from producing and disposing of new rubber materials. By repurposing life tires, we extend their usefulness and contribute to a healthier planet.

Wrapping Up the Loop on Rubber Recycling

The rubber recycling industry is dedicated to refining processes like tire pyrolysis, which turns discarded tires into a valuable fuel source or raw material for civil engineering applications. By participating in recycling programs, we can ensure that materials produced from recycled tires and scrap rubber are reintegrated into the economy. This reduces reliance on virgin rubbers and promotes the use of tires as fuel or in construction, thereby closing the loop on the lifecycle of discarded rubber.